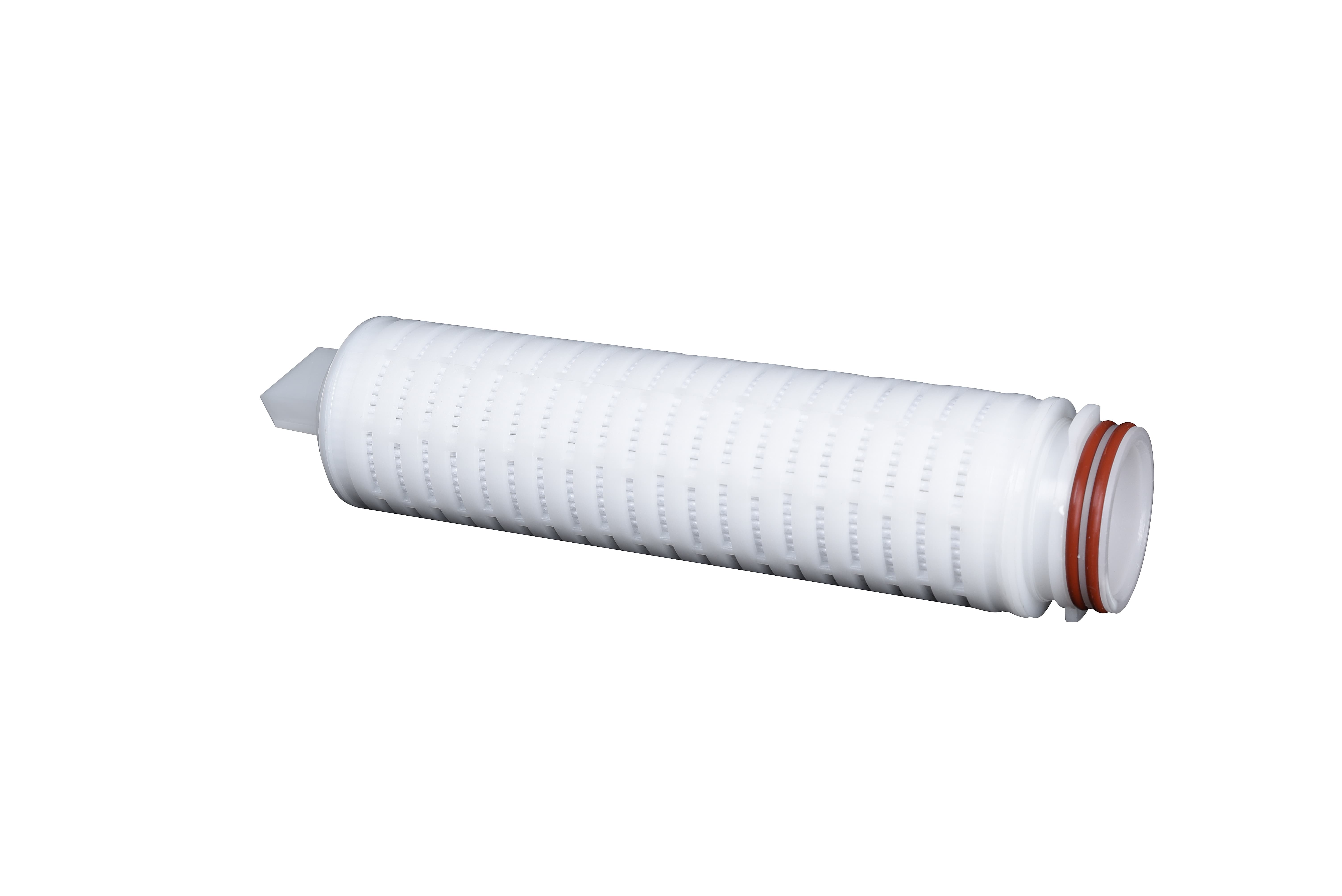

Polypropylene (PP) Cartridge Filter are commonly used in water treatment, air purification, chemical filtration, and other fields. Polypropylene (PP) Cartridge Filters are primarily made from polypropylene (PP), a material that is thermally welded together. Polypropylene (PP) Cartridge Filters are widely used for particle removal in liquid filtration applications such as pharmaceuticals, beverages, and other liquids, meeting filtration quality standards and extending the lifespan of downstream sterilization filters. Additionally, they can intercept solid particulate impurities in the air, effectively reducing particulate content in gases and ensuring clean air.

Polypropylene (PP) Cartridge Filters employ a layered retention mechanism, gradually filtering particles and impurities from water or air. The surface and pore structure of the filter can effectively block larger particles from entering the filtration system, while smaller particles are filtered out.

Polypropylene (PP) Cartridge Filters usually use ultra-fine polypropylene fiber materials that are tightly arranged through thermal welding or other processes to form a fine filtering mesh. This fiber structure has a high surface area, allowing it to effectively capture smaller pollutants such as dust, bacteria, rust, etc.

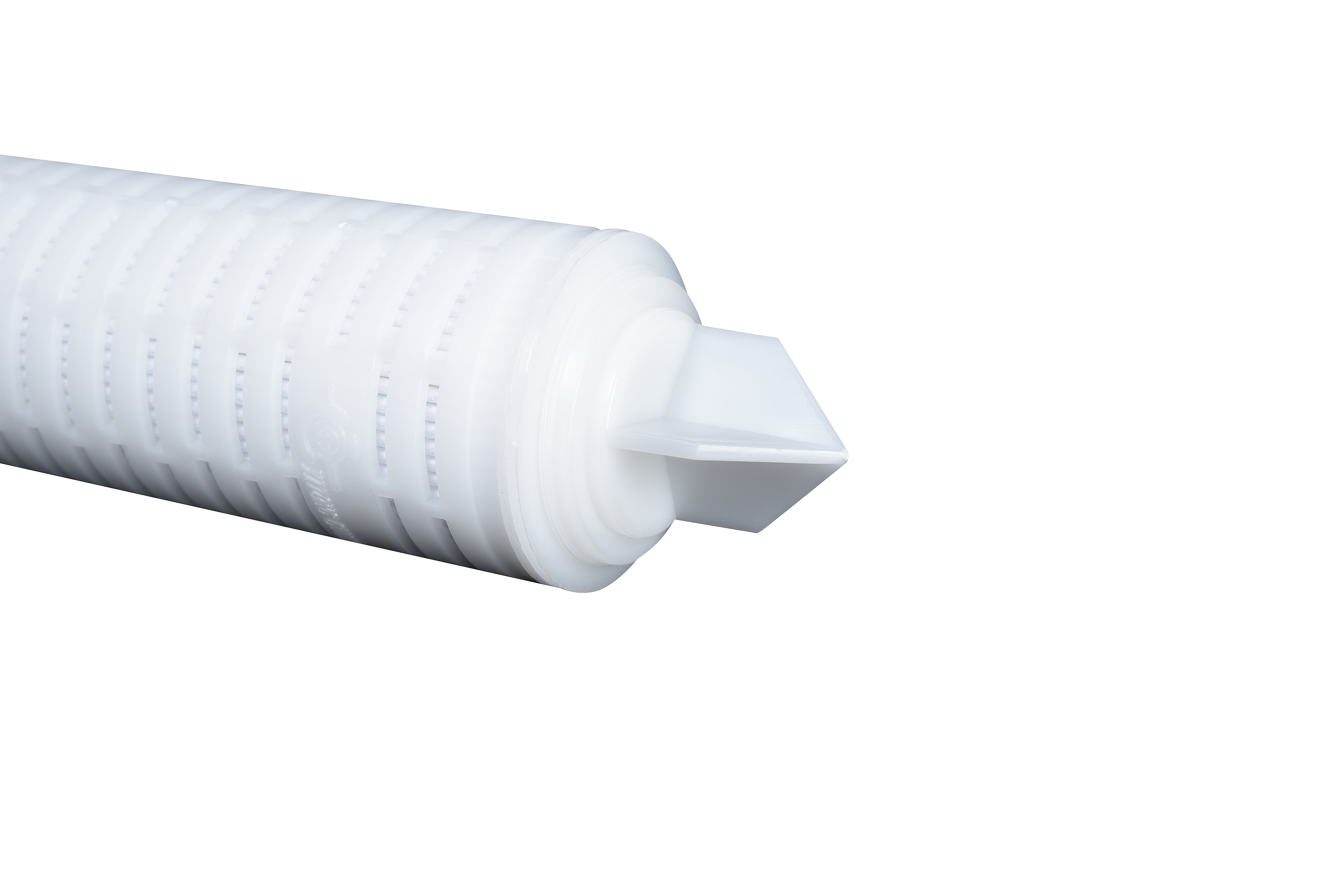

Polypropylene (PP) Cartridge Filters are typically designed with a multi-layer structure, with increasing filtration precision as you move inward. The outer layer has larger pores that primarily block larger particles, while the inner layers with smaller pores remove finer suspended particles and contaminants. This depth filtration method improves filtration efficiency and extends the filter’s lifespan.

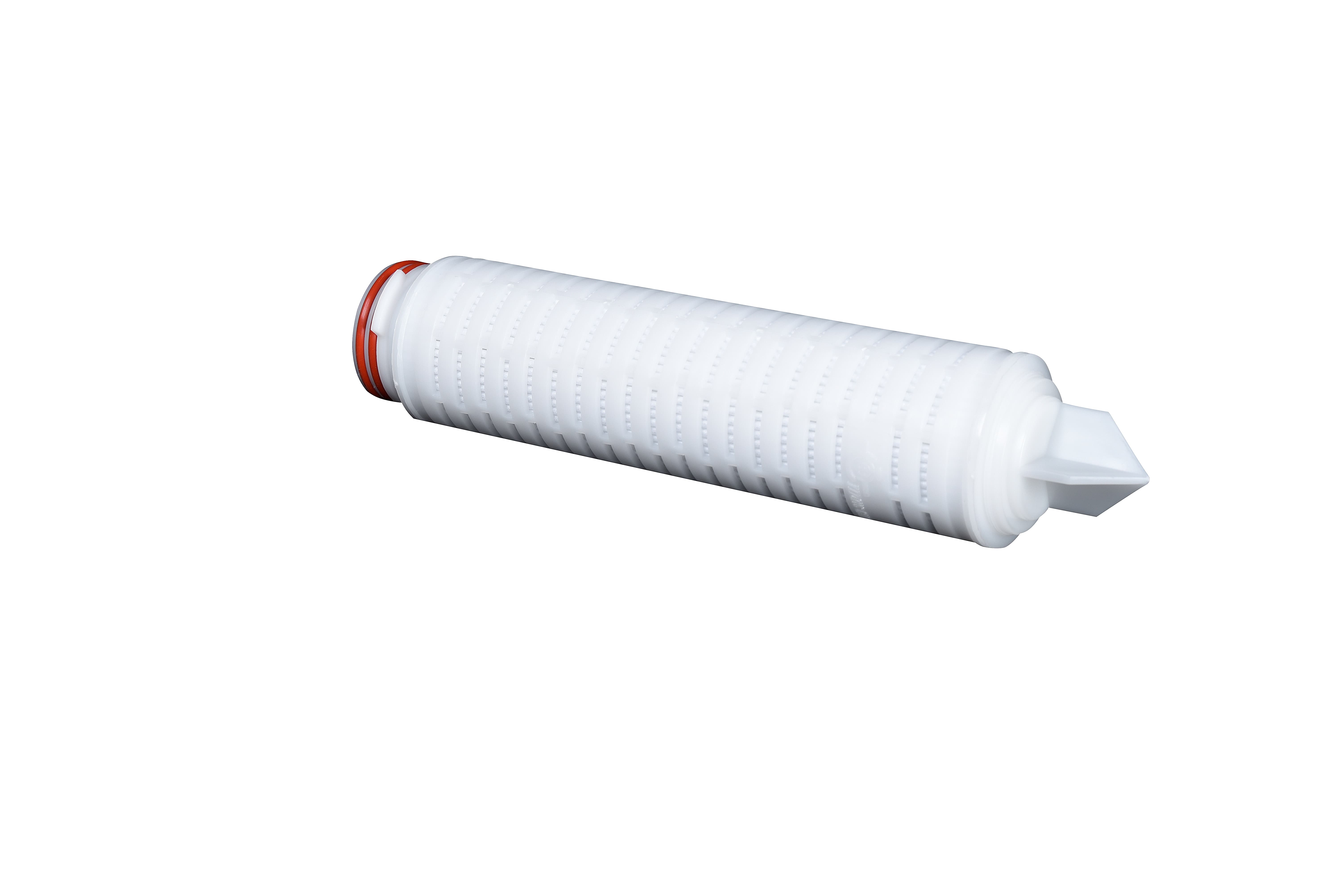

Polypropylene (PP) has excellent chemical inertness, making it resistant to reactions with chemical substances in water, thereby preventing secondary contamination. It is also adaptable to water with varying PH levels.

The pore sizes of Polypropylene (PP) Cartridge Filters are typically very small, allowing them to filter out micron-level impurities (such as 0.1μm, 1μm, etc.). As such, they perform exceptionally well in precise filtration, especially in industries where strict water quality is required, such as electronics, pharmaceuticals, and food and beverages.

1.High Filtration Precision: Effectively removes fine particles, bacteria, rust, and other impurities from water.

2.Long Service Life: The corrosion-resistant properties of polypropylene extend the lifespan of the filter.

3.Chemical Resistance: PP material offers good stability against various acid and alkali solutions, providing broad adaptability.

4.Low Cost: Compared to filters made from other materials, PP filters are cost-effective and offer a high value for money.

5.Easy to Clean and Replace: The simple structure of the PP micro filter makes it easy to clean and maintain.

1.Water Treatment: Such as drinking water, industrial water, wastewater treatment, etc.

2.Food and Beverage Industry: To remove impurities from water and ensure water safety.

3.Pharmaceutical Industry: Used in the preparation of pure water, avoiding contamination in pharmaceutical products.

4.Air Filtration: Used in air purification systems to filter dust, pollen, and other airborne particles.